Characteristics of FLAKE LINING

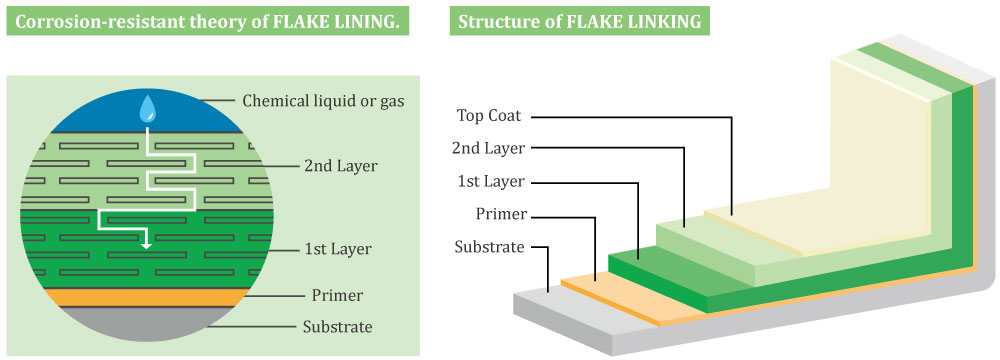

Excellent imperviousness: |

| The horizontal layering of the FLAKE framework forms a tight barrier preventing the infiltration of gas, liquid and steam, thereby extending its infiltration path. |

Strong adhesion: |

| The even distribution of FLAKE, together with the hardening and shrinking of the thin layer leaves very little residual stress in the membrane; therefore, there is strong adhesion between the lining membrane and the matrix to ensure that it will not peel off with pressure. |

Outstanding thermal shock resistance: |

| The FLAKE’s coefficient of expansion is small and the residual stress is also insignificant, therefore it offers excellent thermal variation resistance and insulation. |

Excellent wear-resistance: |

| Experiments reveal that the lining membrane offers excellent wear resistance, wind and sand resistance as well as mechanical friction. |

Excellent constructability: |

| Cures at room temperature to ensure excellent constructability. |

Structural representation

Applicable areas

| According to more than two decades of experience in the Japanese industry, the characteristics of the FLAKE LINING material makes it suitable for anti-corrosion treatment of large Flue Gas Desulfurization Plants. In particular, it is more widely used in thermal power plants and large refuse incinerators. |